Ninja 400 Electronics and GP Bodywork Test

Ninja 400 Electronics and GP Bodywork Testing at Chuckwalla Raceway

I was out at Chuckwalla this weekend of September 14-15th with Jeremy Toye and a couple friends to do some testing and turn some laps to start getting in shape for the CVMA season, which starts in a couple weeks. It’s been an incredibly busy year and I apologize for not posting much riding and testing stuff this past year. I’ll be catching up on articles and info for you all as I get time this fall.

[/av_textblock]

[av_textblock size=” font_color=” color=” av-medium-font-size=” av-small-font-size=” av-mini-font-size=” av_uid=’av-k1fa743p’ admin_preview_bg=”]

I had a few cool things to test out this weekend. First up was two different stand-alone quickshifters for the Ninja 400, the Annitori and the IRC, both of which we sell at Norton Motorsports. Next I would be testing a first revision of my ECU flash built to pair with our Ninja400R Velocity Stacks. I always test any tuning systems on the dyno and on the track before releasing them to customers. I also brought my aRacer RC2 Super ECU and autotuner to test and use as a reference to compare our ECU flash. This system is so awesome, just a step above anything else on the market right now for these Ultra Lightweight bikes. And finally, the thing I’m most excited about, our GP bodywork for the Ninja 400. The Ninja has an amazing engine and great chassis, but I personally can’t stand the bodywork and ergonomics. So I’m on a mission to build a new set of bodywork and ergonomics package for the bike. The whole time I would also be testing the Dunlop MotoAmerica spec slick tires compared to the other options I’d used on the R3 and my current Bridgestone setup. I haven’t really had much time on the Dunlops yet, so this would be a good time to get some back to back time between the two setups.

I actually wasn’t planning on testing the bodywork this weekend, but I was able to just barely get it roughly mounted up, so what the hell, why not. Here I am installing the windscreen super last minute in the morning before riding.

Quickshifter Testing!

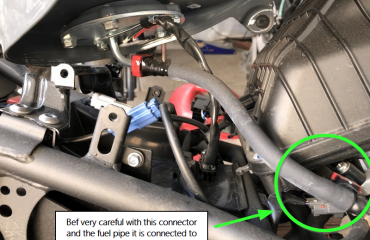

Okay, let’s get to the nitty gritty. First up I’ll talk about quickshifters. I installed the IRC Quickshifter before arriving at the track.

Ninja 400 GP Bodywork, am I crazy or is this awesome???

Okay, now let’s talk about the new GP Bodywork I’m working on for the Kawasaki Ninja 400. Here’s some shots of the prototype bodywork fit up on the bike. (There will be full side panels, I just didn’t get them done and mounted up yet)

aRacer Super RC2 w/ Autotuning

With some solid mental notes on the ECU flash, I swapped the ECU for my aRacer RC2 Super and switched on the autotuner for some laps with the aRacer to compare it to my ECU flash.

About Norton Racing

2 Comments to “ Ninja 400 Electronics and GP Bodywork Test”

You must be logged in to post a comment.

The Annitori can do both up and down QS on the 400?

The Ninja 400 doesn’t have a ride by wire throttle body, so down QS with autoblib is not possible unless you add a solenoid to blip the throttle. The Annitori can be programmed to do upshift in GP or Standard shift configuration.